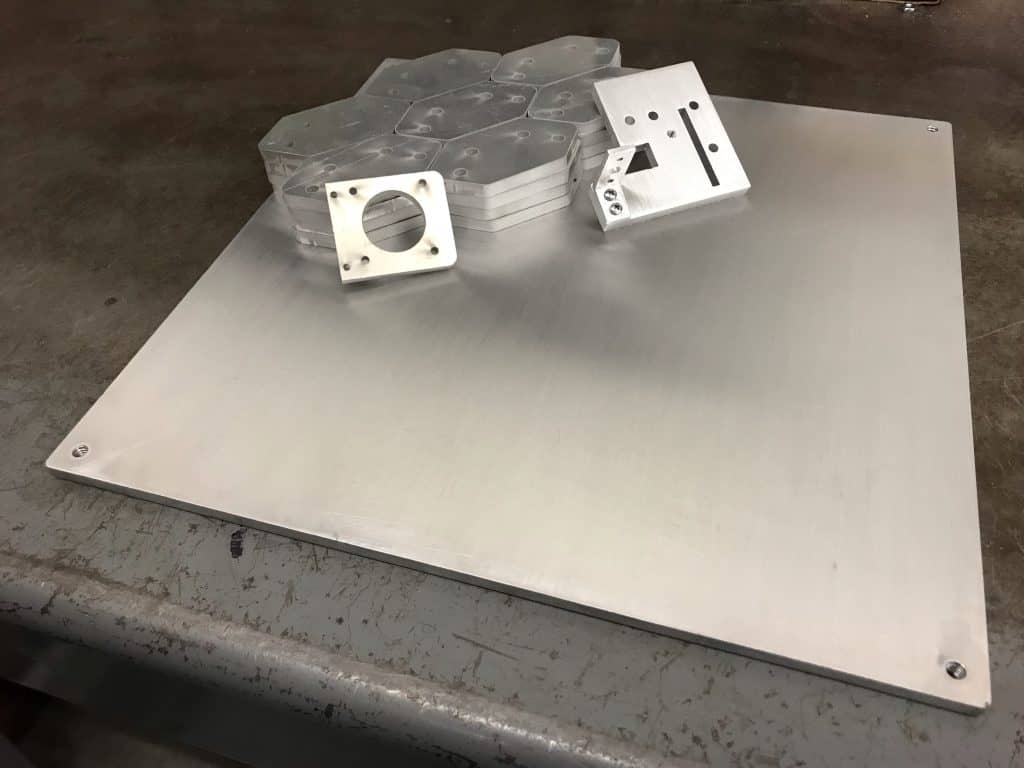

C3DP Team has been making steady progress; we’ve recently waterjet our design for brackets, the heated bed platform, and the X-carriage extruder mount. We’re using a system of dowel pins and a pair of M5 bolts to make the extruder removable, so for example it could be replaced with a newer extruder or even a laser module or dremel attachment for doing light CNC milling.

We’ve based our frame on the “HyperCube Evolution” (Thingiverse Page) with modifications for a larger print volume, more rigid axes, and a completely different extruder. We’ve also designed mounts for the control board we chose (Duet 2 Wifi) and the power supply mount, which covers the normally exposed 120VAC wires, and also passes through a fuse and switch for added protection. The 1/4″ 6061 aluminum brackets are very excessive for this size of printer, but it will aid in rigidity of the frame to make it easier for perspective CNC milling and transporting it to EOH and outreach events without needing too much re-calibration.

Our extruder is a direct drive setup using the Titan Aero by E3D, and a “Volcano” hotend for high filament flow and increased print strength. We will also have a hardended nozzle which allows us to print abrasive filaments like carbon fiber filled filaments. The direct drive setup will also hopefully allow us to have success printing flexible or semi-flexible filaments as well.

We’ll be purchasing most of our parts over winter break so we can begin assembly and printing our all the parts on iRobotics’ Ultimaker 3.