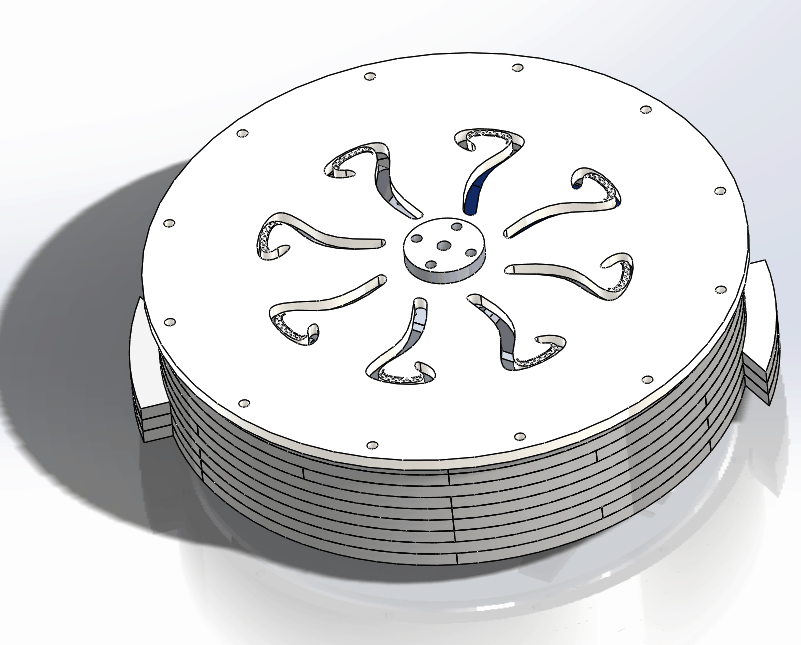

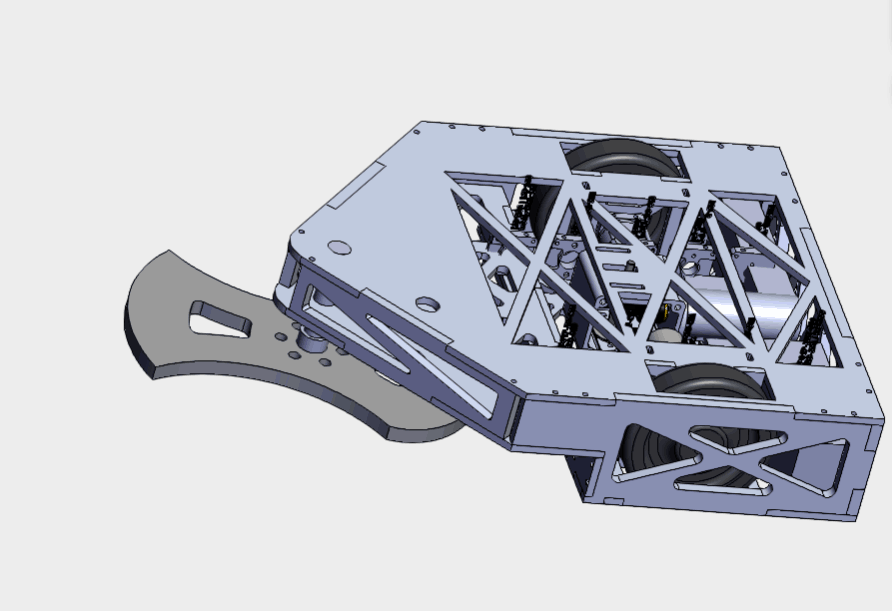

Picking up where we left off, we have all come back from break with some more knowledge of CAD! We kicked off our meetings this semester by finishing up the different CAD components. Once that was done, we moved onto doing weight reduction. We also ran into design issues regarding our weapon once again. We found that the new version was too weak and would have deformed upon contacting another robot. We went through a few more designs before settling on a design that fit our dimension constraints as well as being feasible to machine. Having ordered all of our components and cutting our plates, we moved onto assembly. One of the first challenges we ran into was our weapon motor having an incorrect shaft size, which prompted us to return it and request a replacement. Another control related issue we came across was a broken ESC. It would not exit setup mode, so it was impossible to calibrate, which obviously was a small issue. Another lesson we learned was how valuable machine shop access was. When trying to drill holes into our side plates that would later be tapped, we found that actually drilling them straight was quite the challenge, as well as learning that small errors in measurement make assembly significantly more difficult. We also ran into issues regarding tolerances on our parts due to issues with the waterjet, it was cutting the parts with slightly larger tolerances than intended. This led to parts not fitting properly, namely bearing holes as well as pulleys being too large for the shaft. This leads us into another issue we had with our weapon bevel gearbox, which was the hex shaft. Having a hex shaft led us to having to create our own pulleys, which was not the best idea. We tried looking on the internet for a pulley that would fulfill our needs, but we were unable to find one. Next year, we would like to be more time-efficient and have more clear goals and set deadlines for ourselves. An issue we would like to avoid is last-minute scrambling by ordering parts earlier. All in all, we have learned a lot thanks to the upperclassmen who mentored us through this process and we hope to kick off the next part of our journey with improving our chassis design.